Occupational safety and health are the most basic requirements for a decent work environment. Workers’ productivity greatly depends on the physical conditions and mental demands of the workplace. According to a study published by the Industri ALL Global Union, there have been at least 30 industrial accidents in India since May 2020. Most of the disasters happened while operating heavy machineries and general industrial accidents.

In the Food establishments the food handlers come across numerous health hazards in the form of heat, acid, alkali, wet slippery surface, electricity, pointed or rusted objects and many more. The basic PPE which is provided in an occupational health and safety culture are safety jacket, uniform, shoes, mask, earplug, and helmet. There are various forms of hazards present in the workplace.

It is the responsibility of the employer to ensure the health and safety of their employee. To support and safeguard this, different international standards and guidelines are available such as ISO 45001, OHSAS 18001. Different countries have different labour laws to protect the interests of the working class.

Having appropriate personal protective clothing for all the employees is of utmost importance to ensure their health and safety. The phrase “appropriate protective working” means to identify the workplace hazard and to provide relevant personal protective equipment to mitigate the hazard.

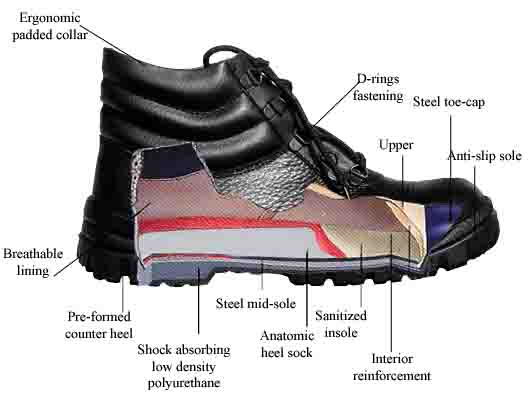

Safety shoes are one such necessity in the workplace to decrease the risk of workplace injury and accidents. It is important to understand what type of safety shoes are best suitable to your plant’s needs. They should provide maximum protection against all possible injuries and should also be comfortable to wear while working on the floor.

The basic requirement to check before getting safety shoes are:

▪ Identify hazards at the workplace such as wet surfaces, slipping, cuts and punctures, chemical splashes, abrasion, sharp objects, and footwear to be efficient to withstand the conditions.

▪ Choose lightweight and comfortable footwear to wear for long hours.

▪ The material used should keep the feet dry and not cause any foot infection.

Certain requirements for the reference to ensure the quality standards:

| IS 15298(Part 2:2016 | Personal protective equipment: Part 2 safety footwear |

| EN ISO 20344:2011 | ‘Personal protective equipment – Test methods for footwear’ |

| EN ISO 20345:2011 – | ‘Personal protective equipment – Safety footwear’ |

| EN ISO 20346:2014 | ‘Personal protective equipment – Protective footwear’ |

| EN ISO 20347:2012 | ‘Personal protective equipment – Occupational footwear’ |

| CSA (Canadian Standards Association) Z195:14 (R2019) | – ‘Protective footwear’ |

| ASTM (American Society for Testing and Materials) F2412-18a – | ‘Standard test methods for footwear protection’ |

| ASTM F2413-18 | – ‘Standard specification for performance for protective (Safety) Toe cap footwear’. |

Safety shoes worn in food handling areas are likely to encounter foodstuffs, water, cleaning agents like caustic, acids, lab chemicals. Choices for the shoes should be made accordingly. The material should be abrasion-free and resistant to water and chemicals. Make sure to know the nature of the foot wear material. The material used is generally:

(a) PU Sole

(b) PU Sole double-density

(c) PU single density

(d) PVC Sole

(e) Rubber sole

The correct type of toe cap is equally important to protect workers against injuries. All the areas of a plant may not require the same type of safety preparedness. Production, storage and loading areas are more prone to cause accidents or crushing the toe as compared to the office areas. Some of the examples are steel, composite, fibre toe caps.

The Compression Strength of the toe cap in the safety shoe is checked to ensure its stability at the workplace. Steel and composite toe caps are used to prevent injury from a falling object, crushing below heavy objects, whereas fibre toe caps are lightweight and can be used for light work areas.

Choice of safety footwear also depends on the temperature conditions within the premises. To deal with hot or cold environments, different materials for safety shoes are required.

CI is the code used to identify shoes used in cold storage areas as per European standard, likewise safety shoes with heat and electric insulating soles are also available. These specially designed footwears need effective insulation properties, which may include thermal linings built into the boot for better insulation.

The safety shoes must be easy to clean. Complicated designs cause food particles to get stuck and accumulate leading to microbial growth. Material of the upper layer should provide ease to remove the stains without the discoloration of the safety shoe. The manufacturer should check the effect of cleaning on the size, shape and function of safety

shoes, and the effective stain removal and range of discoloration and share the instruction clearly as per the outcome. The buyer should read the manufacturer’s instructions carefully and maintain the shoe accordingly.

Occupational accidents have a significant human, social and economic cost, which should be eliminated by ensuring workplace safety. A Healthy and Conscious practice to provide appropriate PPE is the symbol of the effort to ensure a safe and healthy working environment. It is important to ensure that the organization provides safety shoes that are

appropriate for the scope of work. In doing so it not only improves safety and comfort during work but also helps the worker to perform more efficiently.

Author: Disha Majhi, is a Senior Associate Consultant at Food Safety Works. She is an expert in the milk/dairy segment and cares deeply about the environment impact of the packaging.