Thousands of food products are recalled each year due to foreign particles or physical contaminants found by the consumers. These recalls not only cost companies millions of dollars, but they can damage their reputations and put consumer health at risk.

There are many kinds of physical contaminants that can cause harm, if consumed. Some of the examples of physical contaminants are plant stalks, dead insects or pieces of plastic/metal.

As per FDA’s “Compliance Policy Guide”, any foreign objects that are less than 0.3 inch (7mm) may cause trauma or serious injury to persons in special risk groups, such as infants, surgery patients and elderly. Ingestion of a piece of a hard or sharp material such as metal could cause an unsuspecting consumer severe injury, require surgery, or have deadly consequences.

Prevention of metal contamination in food is a big question for the industry that has been there in the picture of food safety and has been an importance to all food manufacturing/ packing industries for a long time.

How do metal particles get into food?

When analyzing existing and potential foreign material hazards, metal fragments are consistently identified as a major concern. As a food manufacturing unit runs on machinery that can break down and wear out there is a huge chance of metal particles contaminating the food. Due to the breakdowns and wears and tears sometimes small pieces of that machinery can end up in a product or package. Metal contaminants can be accidentally introduced in the form of loose pieces of equipment such as nuts, bolts and washers, or metal can break off from other parts such as mesh screens and filters.

Investigation and Identification

Physical contamination, including metal contamination, can happen at every stage of food harvesting, processing, and preparation. Food safety standards emphasize that food products must be inspected several times on their journey from raw ingredients to finished meals.

The hazard of these kinds can be minimized by a proper planning and execution of periodic checks of equipment, calibration and proper maintenance activities like preventive and breakdown maintenance.

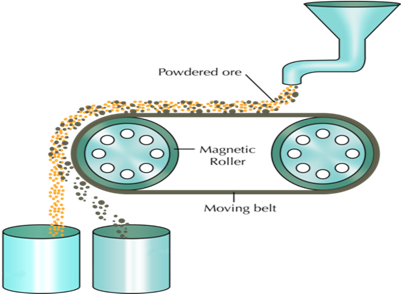

During harvesting and packing of few food products like cocoa beans, nails and other metal fragments are generally observed. To avoid this magnetic drum separator, bullet magnet, cascade magnets, external pole magnets, clean flow magnets are used. The installation and functioning purely depends on the process carried out in the line. The metal fragments that are introduced into a food product, can be removed from the product by passing it through a screen, magnet, flotation tank, electronic metal detectors or 3D modelling software optimized with systems etc. These measures are more likely to be effective in food products in the form of liquids, powders and similar forms as the metal fragments will not become embedded.

For electronic metal detectors, the product alignment, processing factors like ambient humidity, product acidity etc. may affect the conductivity of food products and thus will create an interference signal that might mask the metal unless the detector is properly calibrated.

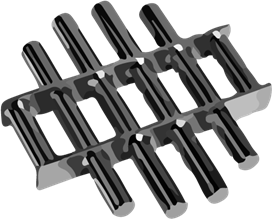

Sticky powders like egg and milk powders will stick onto the food contact surfaces which lead to iron particles getting bonded onto the food. Novel technology like installing rotating clean flow magnets as shown in figure 1 will remove these iron particles as small as 25 microns.

Some pasty products like cheese, desserts can pass through magnetic filters which have neodymium magnetic bars to remove small fragments of iron from food products.

A double walled magnetic filter that works under pressure is used for liquid chocolate, cocoa liqueur etc.

Recently, for India, FSSAI has approved a gravimetric estimation of iron particles using a magnet of strength ~ 1000 gauss for determination of iron filing in tea.

Role of Magnets in the food processing line

It is critical that a magnet program be implemented and maintained in a manner that is effective to the process overall. It is important to monitor and verify the strength of the magnet at a set frequency for effectiveness to provide confidence in the process line in addition to the usual cleaning and inspection. Verification should be done at least annually using a calibrated Gauss meter.

Trained personnel should check the effectiveness by using test probes. Location to place the magnets will depend on the process especially in the final or critical product location and the common are listed below:

- Product, Raw Materials (RM) intakes

- Equipment high impact protection

- Final finished good (FG) / packing line and

- Lab for testing FG and ingredients

Malfunctioning, desensitization are few risks that can include in an ineffective metal detector check control program.

The strength of the magnet at strength of 10,000 Gauss is commonly used in the food industry. A validation of the strength requirement of the magnets needs to be done based on the type of product, placement of magnet, type of equipment, handling practices and many more other parameters. The verification of the magnet strength can be done by passing the known weight of the magnet and checking for the effectiveness of the installed magnet to attract these. Magnets should be cleaned manually or automatically at desired frequency. Food manufacturing companies with a good risk assessment and HACCP Plan will have a detailed procedure to handle and increase the efficiency of magnets so that the hazard can be eliminated to an acceptable level.

It is important to understand that to control the metal contamination, sometimes a magnet may need to be installed along with a metal detector.

Magnet Materials

Following types of materials are commonly used to make magnetic separators:

- Alnico magnets: They are made from aluminium, nickel cobalt and iron. They are used in applications that have high temperatures. It is used to remove relatively large pieces, such as bolts or nuts.

- Ceramic magnets: They are made from a composite of iron oxide and barium/strontium carbonate. They are used to remove relatively large pieces of ferrous metal such as nuts, bolts, nails and other metallic objects in that size.

- Rare Earth magnets: They generate an extremely strong magnetic field, allowing them to remove fine or weakly magnetic contamination such as rust or work-hardened stainless steel from a product flow. Extensively used by the food industry.

Performance of the magnet depends on:

- Temperature: Magnetic materials lose strength when exposed to high temperatures and it cannot be recovered by cooling.

- Equipment Design: Spacing and number of tubes in magnetic equipment affect the strength of the magnetic field it generates. Closer spacing and more tubes means a stronger magnetic field and higher efficiency.

- Flow Characteristics: Many food products exhibit different flow characteristics when damp or moist affecting the flow between the magnetic separator and the product.

- Product Characteristics: Assessing the characteristics of the material that is processed is a key point in selecting the right magnetic separator.

Surprisingly, many companies are still unaware about the requirement of magnets in their processing lines. Some who do install it in their lines, often place the magnets in places where they fit in the process, not necessarily where they would be best for the process. Others have magnets, but have no idea how often they are cleaned and what purpose they are serving.

At a minimum, an effective magnet program should have high strength magnets for all final and critical steps in the process and magnet verification program in defined and regular frequency. Records for the magnet monitoring and verification activities must be maintained.

Author: Mythri R is an Associate Consultant at Food Safety Works. She has been working with a lot of food processing units to ensure they have a robust Food Safety Management System. She is very well conversant with HACCP and ISO22000.