Food safety is a criterion that must be satisfied regardless of the socioeconomic status of every consumer at any point of time. When the safety is compromised it can cause the outbreak of various pathogens or chemical/ physical contamination within food which causes food borne illness or injury to the consumer. The primary goal of food analysis is to guarantee that food which reaches the consumer is safe.

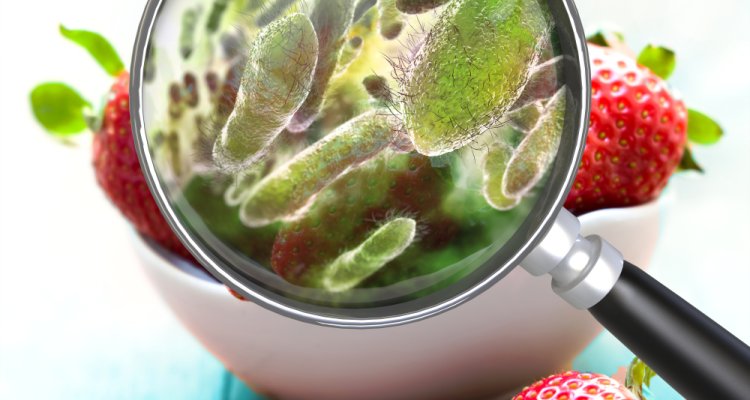

We come across various news related to the contamination incidents in food. E.g Salmonella in lettuce, aflatoxin in peanuts, cadmium in raw rice, PCB-tainted milk powder, mercury in fish and the list goes on thus, food analysis as well as analyzing the data associated with it has become increasingly important.

Who is responsible?

Food safety and quality does not start and end with farms. It’s a global issue that falls within the purview of every stake holder in the food chain right from the producers to the government. Starting from the farmer, good agricultural practice needs to be followed, HACCP & GMP are to be practiced by manufacturers, Good handling practices should be followed throughout the supply chain in order to prevent the contamination.

How can we confirm the food is safe?

The food needs to be tested to confirm its safety and quality. Thus “Food Analysis” plays an important role at this point. Through the analysis of food we can study various characteristics of food, this includes everything from its chemical composition, to how it is packaged, to how it interacts with the human body.

Along with testing the food it is important to collect the relevant data and use it for analyzing the existing situation. Data analysis is the process used to analyze, visualize and utilize the huge volumes of data in order to harness it and help people make better decisions.

What is the importance of food analysis?

Food analysis is an integral part of the food industry. Food analysis is required for a variety of reasons, including determining quality of product, analyzing the nutritional composition of food and to determine the shelf life of products. Care should be taken to ensure that quality of food is tested before it reaches the market shelf. If the food is contaminated, the consumer may not only become unwell, the latter of which has far more long-term consequences. It may also cost the company a lot of money in lawsuits and cause damage to its reputation.

How to choose the method of analysis?

To determine a specific attribute of a food material, a variety of analytical methods are available. Hence, the most suitable method needs to be chosen. The test method depends upon the type of food and the component to be analyzed. There are various methods of analysis ranging from simple techniques to advanced instrumental analysis. Various characteristics can be analyzed; those include Nutrition Analysis, Physico-chemical Analysis, Microbial Analysis, Sensory Analysis etc.

Various international agencies, like ISO, AOAC, and AOCS, have provided formal approval to procedures that have been thoroughly examined by independent experts and proven to be acceptable for food analysis. Analysis needs to be performed with laboratories which are accredited for ISO17025 .

Benefits of Food Analysis

Laboratory analysis primarily ensures the quality of the product. It also helps R&D for new product development, by carrying out analysis the R & D team understands the components that can be used, helps in shelf life study and also for sensory evaluation of the product. Another purpose of this analysis is for the compliance with regulation for the export and import of food to various countries.

But is lab analysis enough to ensure food safety?

Lab analysis will let you know if the product is safe or not but it will not tell you the reason behind repeated product failures. To implement robust food safety plans that guarantee reduced risks and clearer visibility into critical areas, it is important to adapt to the innovations in the food safety industry. Every data point that you collect either through monitoring or laboratory analysis presents an opportunity for valuable analytics that support a dynamic approach to contamination and recall prevention. Food safety data and analytics can reveal a great deal of useful information if you understand how to use them effectively.

The line between data and noise is quite thin. Knowing where to look before you can derive any real benefit from the data you have collected is very important. Some of the examples of the key areas to focus are the HACCP plan, general manufacturing practices, monitoring and verification results, etc.

If the batches of your product are repeatedly tested positive for coli-forms, analyzing the personal hygiene data might help you in seeing how many times your food handlers have faltered in those practices. This will help you in addressing the root cause of the issue rather than just doing the postmortem of the product.

Strong food safety analytics furnish crucial intelligence on every point of contact for a product, which will result in a faster response time to non-conformance.

Conclusion:

Nowadays consumers are more conscious about the food they eat and about the quality of the products. The food industry has become extremely competitive. As a result, manufacturers are focused on the quality. In order to meet the quality of their product they need to implement analytical methodologies throughout the food supply chain, from raw materials to finished products. Technology offers great promise for improving food safety, quality, and access while mitigating food waste. But to realize the promise of digital technologies, the industry must adopt some important changes. Data analysis in food safety remains in infancy but it has a great impact on the entire food supply chain.

Author: Sharanya Shylendran is a Senior Associate Consultant at Food Safety Works. She is an expert at instrumentation and analysis of food as well conducts a lot of audits for us.