A WHO report says, each year 1.8 million people die due to diarrhoeal diseases and most of the cases happen due to contaminated water or food. More than 200 known diseases get transmitted through food. Illness may occur within 1 to 3 days of eating a contaminated food. Sickness could even develop in a span of 20 minutes or up to 6 weeks later. The common symptoms of foodborne illness include vomiting, diarrhea, abdominal pain and sometimes flu-like symptoms such as fever, headache and body ache. Food-borne illness, otherwise known as food poisoning, happens when a person is sick from eating food which has been contaminated with a harmful microorganism that could be a bacteria, parasite or virus.

Most healthy people will be able to recover from a food-borne illness within a short time but, however, some may develop chronic, severe or even life-threatening health conditions. The high-risk category of people includes pregnant women, young children, elderly and people with weakened immune systems.

The most important key to avoid food poisoning is to handle food safely. Proper handling and food processing are vital to serve up a delicious and safe product for consumption. At food establishments, manufacturers must always be concerned with food safety. Proper food handling practices must be followed by all food handlers on ground. Four simple steps- clean, separate, cook and chill can help you at your home as well. Here, are the safe food handling practices detailed in. Also, focussed on, are the safe handling practices for fruits and vegetables.

Clean, Separate, Cook and Chill

The 4 basic safety rules that apply across any food handling area are these.

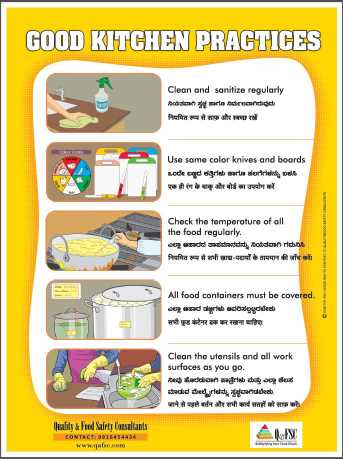

- Clean – Do you think any area around is free of microorganisms? Not even your skin is! Pathogenic bacteria are there everywhere. The key is to keep them away from you and your food. Clean, clean and clean! Clean your working area, utensils, food service equipment and your hands primarily. When holding fresh produce and after preparation, wash your hands and arms thoroughly with soap and water. Keep kitchen surfaces clean in order to protect the processing operations from cross-contamination. Handwashing is an indispensable step to prevent contamination. Wash your hands while handling raw meat and then shifting to handling raw fruits or other foods to prevent cross-contamination.

While preparing the raw foods, the following will help. Remove damaged and bruised areas and wash the produce thoroughly under clean running water. Scrub firm produce like potatoes and cucumbers and rinse under cool water. The produce that are to be peeled must be washed thoroughly before peeling as microorganisms could transfer from rind. Harder-to-clean produce like broccoli, cauliflower may be soaked in cold, clean water for one or two minutes. A sanitizing agent may be used after wash with potable water. Fruits like raspberries which get easily bruised should be put in a colander and sprayed with water. Do not use a soap or detergent on the foods. Dry produce with clean paper towel or cloth. The process of cleaning fruits and vegetables is detailed ahead. With regards to meat, poultry and seafood, USDA says that washing is not necessary as it is already cleaned while processing. Washing these can increase the risk of cross-contamination. Eggs are also washed before getting packed. The cooking temperature is the vital part of handling this class of foods.

- Separate – The main route of pathogenic microorganisms is cross-contamination. Cross-contamination may occur when handling raw produce, perishable food, utensils and finished products and keeping them without separation. Raw foods such as meat, poultry, fish and even fresh fruits and vegetables should be stored separately from minimally processed foods and ready-to-eat foods. The equipment used such as cutting boards and knives should be different for each category of foods and must also be maintained separately.

- Cook – Color and texture are not reliable indicators of food safety. Instead, use food thermometer to ensure the safety of meat, poultry, seafood and egg products for all cooking methods. All these foods must be cooked to a safe minimum internal temperature to destroy any harmful bacteria. Cooked foods will stay fresh longer only if maintained at the safe right temperature.

Chill – Temperature is the primary and most important factor to food safety. Perishable foods must be stored in cold temperatures with quicker cooling within 2 hours at 4 ° C or below to inhibit the growth of spoilage microorganisms. Storage below the freezer temperatures, can stop microbial and enzymatic reactions that can spoil food. Other important safe practices include safe thawing and correct storage times and temperatures.

Practices for handling fruits and vegetables

The risk of foodborne illness from consumption of fresh fruits and vegetables can be higher as they are eaten raw or minimally processed. Once fresh produce is contaminated by microorganisms, they are

difficult to wash off. Hence, it is vital that contaminants are avoided on the first hand! Washing with clean running water, can help reduce the number of microorganisms on fresh produce by about 99%. But cannot ensure the complete removal of pathogens. Storage of fruits and vegetables under the right temperature control and appropriate cleaning and sanitatizing practices can reduce the risk of foodborne illness. Have a look here through the important practices that can help control microbial hazards across various stages such as – purchasing and receiving, storage, food handler, preparation and service.

Purchasing and receiving

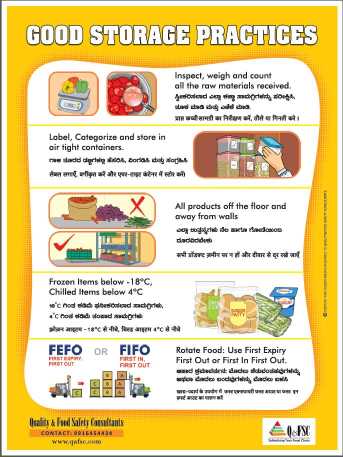

- Safe and trusted sources should be chosen to purchase the produce. Also, maintain the produce safe right from the receival through the service.

- Follow supplier recommendations, if any regarding the handling, storage temperatures, shelf life etc.

- Avoid receiving any damaged materials.

- Ensure that all records with respect to the purchase of fresh produce are maintained.

Storage

- Store the raw materials separately so that it does not get contaminated or cause cross-contamination.

- Ensure the washed or cut produce is separately stored from unwashed, uncut produce.

- All the foods must be kept off the floor (at least 6 inches off the floor).

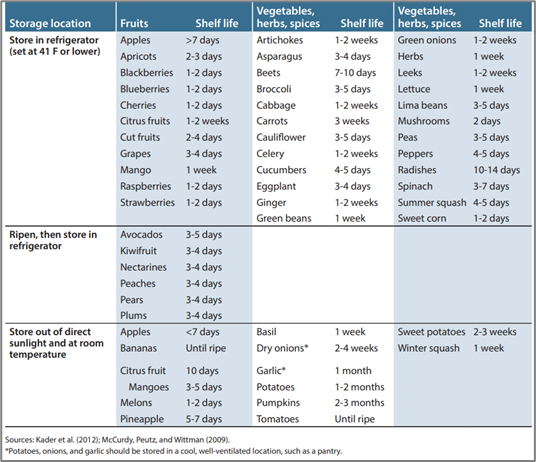

- All the fresh produce must be stored at the appropriate temperature.

Below given is set of recommended storage temperature and shelf life of common produce items.

Food Handler

- Wash your hands thoroughly with soap warm running water before and after handling fresh produce.

- Avoid bare hand contact while preparing and serving fresh produce. Make sure to use gloves or tongs.

- Ensure if ill, food service employees do not work.

Preparation

- Wash, rinse and sanitize all equipment including all sinks, utensils, cutting boards, slicers and all food preparation surfaces before and after handling fresh produce. Designate specific cutting boards and utensils for fresh produce.

- In case of produce like, cabbage, lettuce, berries and tomatoes, remove outer leaves, stems and hulls.

- Wash fresh produce under running, potable water before use. Take care in case of washing sensitive produce such as berries, grapes etc. Wash these immediately before use.

- Do not use non-food grade soap or detergent on fresh produce.

- Rinse fresh produce under running tap water. Spray or Scrub firm fruits and vegetables such as potatoes and carrots under running tap water, if possible, to remove any dirt and mud.

- Do not soak or store produce in standing water or ice.

- In order to reduce microorganism and pathogens fresh produce can be treated with a sanitizing agent post wash with potable water.

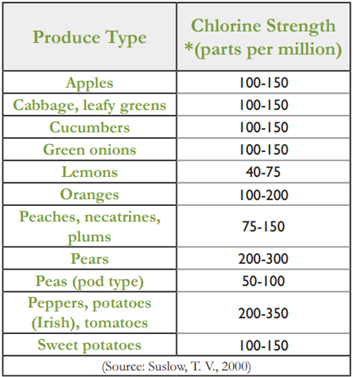

- Chlorine can be used in wash water for produce such as apples, nectarines, plums, cherries, grapes, leafy greens, peppers, tomatoes, peas, melons, cabbage, green onions, cucumbers and zucchini.

- The temperature of wash water shall be maintained between 12.8 ° C and 48.9 ° C, which is when chlorine dissolved in will be most effective. If the water is colder the produce, then the plant and human pathogens would get sucked into the fruit which cannot then be removed by chlorine.

- The disinfectant solution can be prepared by adding the measured mix of chlorine into potable water. The concentration of chlorine solution will vary with the type of produce.

- The table shows recommended chlorine solution concentration for some of the fresh produce. A minimum contact time of 1 minute is required to ensure all the pathogens are killed. Chlorine test strips can be used to test the chlorine concentration.

- Chlorine is most effective when pH of water is maintained between 6 and 7.

- Rinse produces with clean potable water following chlorine treatment and air-dry in a clean and closed area.

- Wash water must be changed frequently as it gets dirty and new crop is added. Also, record all the practice – date, time, chlorine concentration (ppm), water temperature, contact time etc.

- Also, refer the manufacturer’s instructions on the sanitizing agent that is used.

- Label and date all the foods.

Service

- At the service, present small batches of fresh produce and monitor the temperature of the service unit and the food.

- Fresh produce should not be placed directly on ice. New batches should be placed in a new container.

- Use appropriate utensils.

- Throw away fresh fruits and vegetables which have not been refrigerated (5°C or below) within two hours of cutting, peeling or preparation.

How can Food Safety Works help?

We deliver training sessions on food safety and allied subjects; webinars involving pioneers across various domains and conduct certification courses recognized by the FSSAI for food handlers. We can help identify and resolve food safety issues, provide knowledge on the right practices of food handling across the food chain and standardize the food safety management system.

Who we are?

We at Food Safety Works have a team of experts with over 200+ years of collective experience.

Started as “Quality and Food Safety Consultants” in 2009, the company was established to bridge the knowledge gap in the industry about Food Safety Management Systems. We take a 360-degree view of food safety starting with design, implementation and monitoring.