The Role of Indicators in Enhancing Product Safety and Quality

1/3rd of the food produced globally is lost or wasted annually. Smart packaging thus offers a new approach to reducing food waste and loss. Not only protecting food from the environment it also extends the shelf life and holds promise for brand objectives like traceability, recyclability, consumer engagement, and supply chain logistics.

The four primary purposes of traditional packaging are preservation and protection (Protect food against Heat, Light, Smell, Microbial and Chemical Contamination, Insects, Dirt, and Dust, etc.), Convenience (ready-to-eat foods that are simple to handle, like resealable containers that are microwave-safe), Containment (available in a variety of sizes and shapes), and Communication (providing information like the brand logo, a list of nutrients, a list of ingredients, a price, preparation guidelines, an expiration date, etc.).

Although new demands like population growth, changes in consumer behaviour and manufacturing techniques, as well as environmental consciousness and emerging technologies like nanotechnology and biotechnology, served as the catalyst for the development of smart food packaging.

Active and intelligent packaging are two different concepts of smart packaging.

Active packaging is a way of packaging where intentional components are incorporated that would release or absorb substances into or from the packaged food or the environment surrounding the food to improve the shelf life of the product or quality and can be categorized as releasing or absorbing systems (Carbon dioxide scavenger, Oxygen scavenger, Ethanol emitters, Ethylene scavenger, Antimicrobial, and Antioxidant releasers)

The active package interacts with the food inside and helps to improve the shelf life. A great example is the increased shelf life of beer from three to six months by adding oxygen absorbers to the cap of the bottle.

Intelligent packaging is a packaging system that uses the internal or external package environment as “information” to monitor the status of product quality, track the product, and identify the hazards during transportation and storage.

On the other hand, Intelligent packaging does not affect the food. Intelligent packaging can be achieved by Indicators, Sensors, and Data carriers, which look like the future and will discuss in a little more in detail. Let’s discuss the Indicators a little more in detail.

Indicators

An indicator is a type of intelligent packaging that sends information about the presence or absence of a particular substance, whether a reaction is occurring, and the substance’s concentration. Time-temperature indicators, Freshness indicators, and Gas indicators are the three broad categories for indicators.

Time Temperature Indicator(TTI)

The shelf life of food products is significantly influenced by temperature, especially for perishable foods. A visual summary of temperature changes is provided by the time-temperature indicator. This is mostly utilized in meals that are sensitive to temperature, such as chilled and frozen foods.

2 main types of TTI are:

- Partial temperature indicator (which does not respond unless the predetermined threshold temperature is exceeded).

- Full history indicators (Which respond continuously to all temperatures).

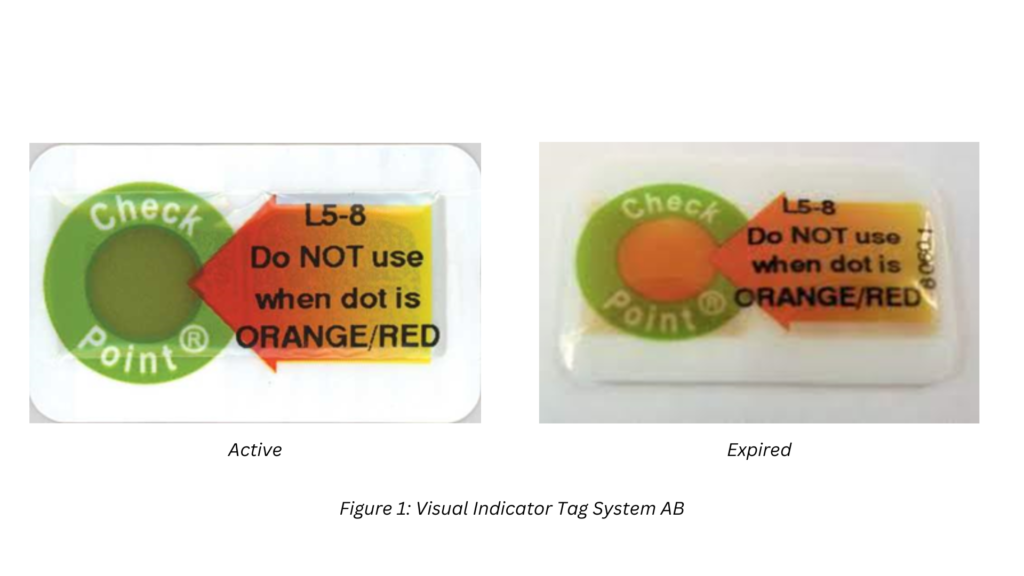

VITSAB TTI

A Swedish research and development company named Vitsab International AB created labels calibrated to reflect bacteria growth and adhere to temperature monitoring rules. The spotlight progressively shifts from green to red if there are any temperature variations.

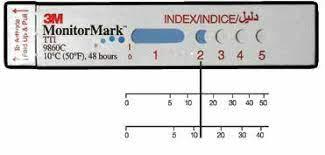

This is another one which is available from 3M Monitor Mark. It is a diffusion-based indicator label that changes colour when a chemical system that is oxidizable is exposed to air, and the colour change is regulated by the amount of air passing through a film. A fatty acid ester that has been coloured blue diffuses along a wick to initiate the activity. Response of the indicator is measured by the passage of the blue dye along the track, and this is complete when all 5 windows are blue.

Figure 2: 3 M Monitor mark

Freshness indicators

Freshness indicators are intelligent devices that allow the monitoring of the quality of food products and indicate spoilage or freshness of the packaged product through colour changes directly detected by the naked eye. Freshness indicators are based on the use of dyes sensitive to pH variations caused by the deterioration of the product, which leads to a visible change in the colour of the indicator.

Food Fresh

Food fresh TM indicators, a class of timers that may be adjusted to expire within a specified “consume within” time limit, ranging from a few days to several weeks or months, were created by the Vanprob company. They are a practical remedy for the issue of food storage following opening.

A label applicator can be used to apply the food fresh sign, which is shown in Fig 3., to products such as jars, vacuum-packaged items, or cartons. The PET labels are less than 50 microns thick and constructed of PET.

Figure 3: Food fresh indicator

RipeSense

Many fruits do not show visible signs of ripening, due to which, the customers find it difficult to recognize whether the fruit has reached its preferred state of ripeness or not. The ripe sense will eliminate this barrier and also help in reducing food waste. The pack comes with a colour-changing sensor spot, which shows exactly how ripe the fruit is.

The RipeSense is the first intelligent sensor label that works by reacting to aromas released by the fruit, indicating the ripeness of the fruit. The sensor is initially red and graduates to orange and finally turns to yellow. This allows the customers to choose the fruit based on maturity. The recyclable ripeSense® pack provides improved hygiene security as it protects the fruit from being handled or squeezed by other shoppers.

Figure 4: RipeSense

Gas indicators:

For use in polymeric films for packaging systems, a chemical dye-based visual carbon dioxide indicator is being developed. In addition to providing information on the CO2 levels inside the packaging, this non-destructive film can help spot early spoiling. No matter the temperature, the system is based on a pH-dependent color shift. The indicator’s colour changes as a result of changes in pH brought on by variations in CO2 concentration.

The gas composition in the package headspace can alter because of the gas produced by lipid oxidation and microbiological deterioration. Gas indicators can therefore track gaseous changes and alert consumers to the safety and quality of food goods. These indications can be printed on packing films or presented as labels. These indicators change colour because of chemical or enzymatic reactions, providing information on the presence and absence of oxygen or carbon dioxide. To have direct touch with the gases created during spoiling, the gas indicators are typically printed or immobilized inside the package.

The definition of modified atmosphere packaging (MAP) is the substitution of air in a pack with a predetermined combination of gases, with fixed proportions of each component and no additional control during storage. The main gases in MAP products are oxygen and carbon dioxide, therefore employing gas indicators can help create controlled environment packaging, where the composition of gases is continuously regulated throughout storage.

Conclusion

Smart packaging offers a sustainable solution to increase the functionality of product packaging to serve a variety of different demands. Its benefits are pretty evident. Several clever packaging methods have developed during the past few years. When these technologies are included in food packaging, they can be valuable in providing information about the product in addition to extending the shelf life of food while enhancing quality. To create solutions that are more affordable while providing ease to the user, a more thorough study is still needed in the field of intelligent packaging materials.

Although most customers would be prepared to pay more for better quality and more product information, they rarely do. Customers might be more inclined to spend more on food with intelligent packaging if they were well-informed about the systems’ advantages. Moreover, consumers’ faith in the security of the systems needs to be boosted. Thus, more actions to promote the technologies should be implemented. The producer must also understand that using clever packaging can provide them with a genuine competitive advantage. A wider application of intelligent packaging would be achievable if all these challenges could be overcome.

How can we help?

Are you having trouble deciding which smart packaging is ideal for your product? We are able to assist you with that. We, as your trusted partner, will provide expert guidance and support in selecting the most suitable intelligent packaging indicators for your product.

Ms. Aswathy CS is an emerging food technologist, who works with the client to implement the FSMS within their organization. She is working as an associate consultant at food safety works.